April 29, 2020

Did you know where in the world is the Silicon Valley of biodegradable medical implants? It is in Tampere, Finland. Arctic Biomaterials develops implants and ecological alternatives to traditional plastics there. The market is virtually unlimited – as long as the IP protection of inventions is in order for sure.

Arctic Biomaterials originated from a problem: biodegradable medical implants were not strong enough. The applications for biodegradable implants include, for example, fractures. In mending them, a biodegradable implant has the advantage of making repeat surgery unnecessary, unlike when using metal plates and screws.

Arctic Biomaterials was founded in 2014 and began developing a bioresorbable and bioactive product.

Bioresorbable means that the substance dissolves or breaks down and is eliminated from the body. Bioactive, in turn, means that the material also promotes ossification by releasing ions and calcium phosphate that help bone cells attach and produce new bone.

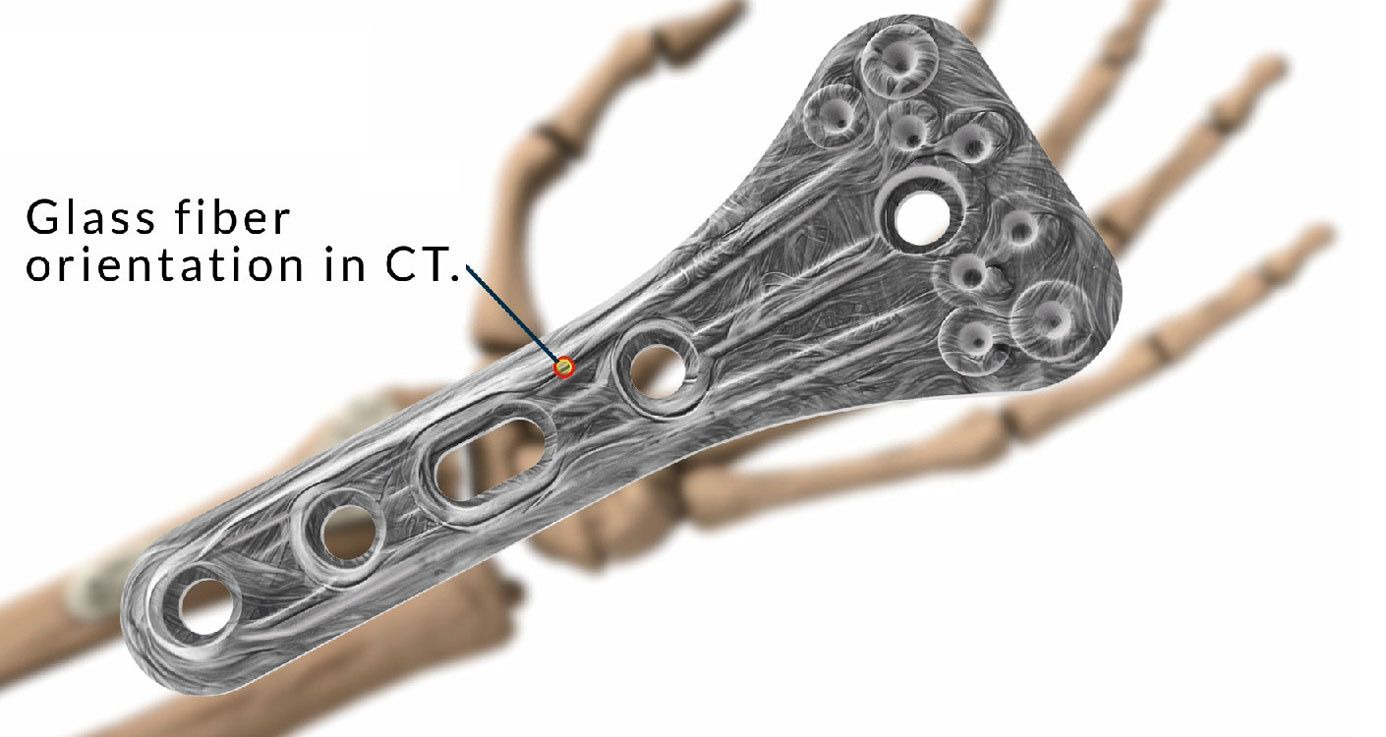

The breakthrough came in 2016 when Arctic Biomaterials managed to combine glass fibre and plastic by developing an adhesion layer that attaches the fibre tightly to the polymer. The reason why the company was founded was reached, obtaining a material with sufficient strength and heat resistance for technical and medical purposes.

It was a major turning point.

“Our unique expertise is polymer know-how combined with fibre technology”, says Arctic Biomaterials’ Executive Vice President Miika Lehtola.

Executive Vice President Miika Lehtola (right) and Research and Development Director Ari Rosling praise the development-oriented atmosphere of their company – everyone has a strong desire to create something new.

Main picture: Arctic Biomaterials’ operations are strongly focused on product development and research. The laboratory facilities are in Tampere in Finland.

A company with awareness understands IPR as a continuous process

“The industry is so competitive that you have no business in this field without IP protection”, Lehtola says.

Kolster’s European Patent Attorney and head of the chemistry team Krister Karlsson praises the company’s awareness.

“The people at Arctic understood from the outset that it is necessary to grow the IPR portfolio, which requires ongoing efforts. The IPR issues of a company based on research and development cannot be a single project that you need to get out of the way, but an ongoing process”, Karlsson says.

Even though the experts at Arctic Biomaterials have IPR expertise in their own right, they wanted to involve a reliable and long-term IPR partner. You cannot manage without a professional.

“Arctic Biomaterials’ innovation is based on strong product development. They are free to focus on that and we at Kolster focus on protecting their inventions. That makes cooperation easy and direct”, Kolster’s Karlsson says.

Replacing oil-based plastic with biodegradable opens doors to becoming a mass production partner

Arctic Biomaterials’ Research and Development Director Ari Rosling has calculated that the company’s staff has a total of 618 years of experience in the biomaterials industry.

The number of employees is 63. The majority of the staff are people with M.Sc. and doctoral degrees engaged in development work, and hiring experts is an important part of the company’s strategy.

“There is no development without these propeller heads, that is, innovative and ambitious workers”, Rosling says.

Arctic Biomaterials’ medical development work has rapidly spawned other innovations as well. Not all consumer products or packaging need to be as strong as medical implants. The medical side was quickly accompanied by the development of technical biodegradable plastics for consumers and industry. ABM now develops and manufactures reinforced and non-reinforced bioplastics in parallel.

The change meant significantly more customers and potential customers – and the opportunity to develop products that will eventually end up in mass production.

“In the beginning, we mapped out really extensively what we wanted to be involved in. Would it be the automotive industry or space? Now we are getting more and more focused all the time”, says Miika Lehtola.

Currently, in addition to implants needed in medicine, development work is focusing on kitchenware, cosmetics and consumer packaging. The development of the medical and technical side go hand in hand and are mutually supportive. Expertise and know-how are disseminated within the company.

“Any time either side has a breakthrough, it drives the development of the other side forward”, Ari Rosling says.

The medical side, for example, has advanced to developing the antibacterial properties of the reinforced material.

A splint intended for the treatment of a wrist fracture is bioresorbed, i.e. it breaks down in the body while also helping with ossification.

Patent families are needed instead of individual patents

The company also develops manufacturing technologies, and Arctic Biomaterials’ portfolio includes both material and manufacturing technology patents.

“For a company like us, it is important that development is built around diverse patent families. We will not succeed by applying for an individual patent to restrict what others do.”

The company currently has about 13 patent applications filed and the same number pending. Preparing patent applications is at the heart of the cooperation between Kolster and Arctic. However, in a competitive industry, it helps tremendously that your IPR partner also understands and conducts novelty searches, freedom to operate analyses and competitor surveys.

They provide Arctic Biomaterials with up-to-date information on what is happening on the industry market – and allow the company to focus on innovation while Kolster takes care of monitoring.

Biodegradable materials to fight against climate change

A company like Arctic Biomaterials has every opportunity for strong growth, as the world is currently crying out for ecologically sustainable solutions. Rosling and Lehtola believe that between 2030 and 2040, 25–30% plastics globally will be bio-based.

“There are indications of a really major shift: the use of fossil-based plastics will be banned in many disposable products, and the use of plastics that produce long-lasting microplastics will be restricted. Plastics straws will be gone, China will ban plastic bags altogether”, Lehtola lists.

It is the goal of many large global players to start using environmentally friendly products. That means a huge international market for Arctic Biomaterials.

“However, it must be remembered that we are developing materials that are 3 to 5 times more expensive than the oil-based plastics currently in use. The properties of the bioplastics we have developed are so good that they can really replace the original oil-based product for the same purpose. We need to reconcile the needs of customers with our own development work”, Lehtola says.

Arctic Biomaterials wants to be involved in defining the industry – and its terminology. The goal is to change the world.

“The field is confusing. People talk about bio-based and biodegradable materials. It is extremely important for customers and, ultimately, for the consumer in part as well, to distinguish what is being marketed and how. Industrially compostable material cannot be thrown into the forest to decompose”, Lehtola points out. Marketing through greenwashing harms the entire industry.

Arctic Biomaterials also manufactures and designs consumer goods and packaging from biodegradable plastic.

Ecological growth plan

The company’s growth plan is also in line with an ecological angle:

“We plan to expand so that manufacturing is as close to the customer as possible. We do not want to transport products around the world”, Lehtola says.

This means that Arctic Biomaterials’ biodegradable materials and products will be manufactured on several different continents in the future.

For companies in the field of chemical technology, global thinking is mandatory anyway. Finland or even Europe is not enough. The assumption is that when you start applying for a new patent, it must be obtained in several countries right away. An ecological mindset can also help the company itself in this area.

Krister Karlsson reminds companies in the field of fast-track processing, which is available at no extra charge when the invention concerns bioeconomy, circular economy or clean technology solutions.

Want to discuss the protection of your innovation in life sciences and biochemistry?

Krister Karlsson

Associate Partner, Head of Biotech & Chemistry, European Patent Attorney

krister.karlsson@kolster.com

044 236 5676

READ MORE CLIENT STORIES

IPR protect the innovations of circular economy developer Ductor

Grip and glide! Vauhti Speed races to the global top of ski wax

The success of Plantui's smart gardens has its roots in IPR